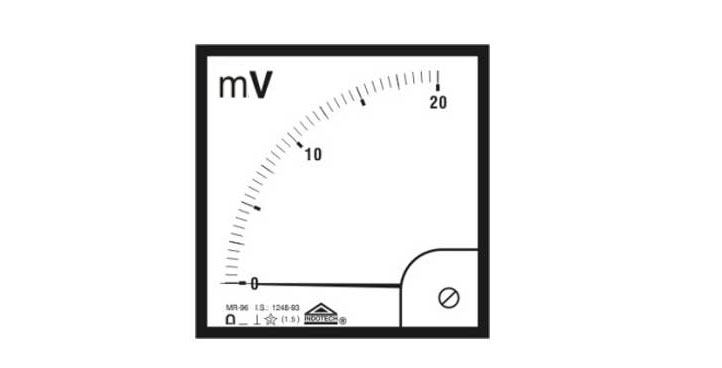

Analog Milli Voltmeter

Indotech Analog Milli Voltmeter – Which means it meters or measures AC voltage or DC voltage in Millivolt range. A Millivolt Meter is a thousandth of a volt. 1Volt is 1000millivolt. A voltmeter is an instrument used for measuring electrical potential difference between two points in an electric circuit. Analog voltmeters move a pointer across a scale in proportion to the voltage of the circuit; digital milli voltmeters give a numerical display of milli voltage by use of an analog to digital converter.

Indotech Analog Milli Voltmeter use solid-state components and display values digitally. Typically, Analog millivolt meter (analog volt milli meters) can be used to locate excessive resistance that may indicate an open circuit or ground. They are also used to identify low milli voltage or milli voltage drops that may indicate a poor connection. The positive lead is connected to the circuits positive side and the negative lead is connected to the circuits ground.

The Analog Millivolt Meter internal resistance is the impedance, which is usually expressed in ohms per volt. This amount is relatively high in order to prevent the device from drawing significant current and disturbing the operation of the circuit being tested. The sensitivity of the voltmeter determines the range of milli voltages that analog milli voltmeter can measure.

‘‘INDOTECH’’ MilliVolt Meter have been found indespensible by Laboratories and Industrial Houses. All the components used in the manufacture of the instruments are selective and are designed to ensure long term accuracy and service. All parts/sub-assemblies are throughly inspected and gauged at all stages with utmost care by experts. Analog Millivolt Meter, analog milli voltmeter, ac milli voltmeter, milli voltmeter

TYPE OF METERS : Milli Voltmeters

The movements are strongly constructed incorporating synthetic sapphire jewel bearings, hard chrome plated highly polished pivots and phosphor-bronze cadmium copper hair springs. Moving coil meters are fitted with high flux density magnets resulting in linear scale. All these meters have zero adjuster accessible from the front.

MOVING COIL TYPE METERS :

These are meant for measuring AC quantities. However, DC quantities could also be measured but with slightly low accuracy. These are available in 90O movement.

MOVING COIL RECTIFIER TYPE METERS :

Moving Coil instruments are meant for the measurement of DC voltages and currents. All the meters are fitted with high flux density magnets resulting in linear scale. These are available in both 900&2400 movements. Analog Millivolt Meter, analog milli voltmeter, ac milli voltmeter, milli voltmeter

PARAMETERS AVAILABLE :

Meters are available for the measurement of mV, V,mA & A, KV meters are calibrated in terms of PT ratio & high range Voltmeter in terms of CT ratio. Analog Millivolt Meter, analog milli voltmeter, ac milli voltmeter, milli voltmeter

NOTE :

1. Mode l s SR72/MR72, SR96/MR96 & SR144/MR144 have changeable dial for different CT Ratios in case of Moving Iron Meters and different FSD for Shunt operated meters in case of Moving Coil Meters of 90′ movements.

2. Dials for 2400 movement meters are not changeable.

| Test | Results |

| VIBRATION TEST : | The meters are subjected to vibrations. This test ensures that if there is any loose component, it will be detected before the meter is passed. |

| LIFE TEST : | The meter is subjected from zero to full scale and the counter meter records the number of operations. |

| OVER LOAD TEST : | The meter is over loaded 120% of its rated capacity for 2 hours. |

| HIGH VOLTAGE BREAKDOWN TEST : | The meter should withstand 2kV, AC, if applied between electrical circuit and any metallic point of the meter for 1 minute. |

| INSULATION RESISTANCE TEST : | BIS1248-03 specifies that the insulation resistance should be above 5 meg-ohms. The test is performed accordingly. |

| ACCURACY TEST : | The accuracy test is performed as per BIS 1248-03. The error is calculated on the basis of full scale deflection of the meter. |